Now that the fueling and displacement is sorted, let's finish up with intake, cams and engine dynamics.

Once your get your fueling sorted out, it only makes sense to work on the air intake and in a basic 4 cylinder car, the more air/fuel mixture you cram into the cylinder, the more power you can extract out of it. One of the tricks tuners like Skunk do is to tune the length, shape, size and parameters of the intake manifold.

Picture courtesy of Zerotohundred.com

Picture courtesy of Zerotohundred.com

When your engine starts to suck in air, the air in the intake moves rapidly towards the cylinder. The valve opens and closes based on your camshafts design and shape. The minute the valve closes, air is packed in, forming an area of high pressure just before the cylinder and the intake manifold runner (somewhere around there). If the intake is correctly tuned, that pressure will help cram more air into the cylinder just as the valve opens for the next cycle.

And like I said - More air + more fuel = more power.

Having said that though, the moment of high pressure is so short, it's impossible for the unequipped to know for sure whether or not there was any gain, but most butt dynos will tell you that you're getting more kick every time you floor the pedal. With the right intake system, believe me it's not a placebo.

The camshaft determines when the intake valves open to suck in air and when the exhaust valves open to expel the exhaust gases, and how it does that is by the "lobes" on the cams that push open either the intake or the exhaust valves (which closes shut right after the lobe turns away, by means of the valve spring).

First of all, the intake valve opens once the piston starts to take its intake stroke (downwards). The air in the intake runner gets crammed into the cylinder really quickly. Your engine runs at minimally 750 revolutions per minute or rpm (normal idling speed). On average Mr. Joe Blow will rev his car to minimally 4000rpm and that translates to the intakes opening and closing 2000 times per minute. If you think about it, that's 33 times per second, the air is moving pretty damn fast.

Picture courtesy of Marshall Brain @ Howstuffworks

Picture courtesy of Marshall Brain @ Howstuffworks

When the intake valve closes, all of that fast moving air would get disrupted and not enter the cylinder. By leaving the intake valve open a little longer, the momentum of the fast-moving air continues to cram into the cylinder as the piston starts its compression stroke (upwards).

So the faster the engine goes, the faster the air moves and the longer we want the intake valve to stay open. Leaving the valve open that slightly longer results in more air being crammed in.

Why? More air + more fuel = more power

And how is this done? With aftermarket cams. Why? Because these cams have higher lobes which open the valve longer.

Picture courtesy of Drex Chan @ EA Autoworks

Picture courtesy of Drex Chan @ EA Autoworks

Now, there's a downside to installing a performance cam. Depending on the degree, angle and height of the lobe, any sort of valve opening overlap for the intake and exhaust will result in rough idling. How bad the idling is depends on how aggressive your cam is. My personal experience was with a mild 260 intake 288 exhaust cam which by racing standards is Hello Kitty. Thundercat cams like the 292 intake 292 exhaust or more will require engine management otherwise your car will stall every time you idle.

But what does this do all in all? Increase power at the tuned powerband. In my case, it was tuned to kick in at 4.5k rpm all the way to 6k rpm. It's a bit high but my car was a basic SOHC (single over head cam) car which means the intake and exhaust are solely dependent on a single camshaft. DOHC (double over head cam) allows you to play with the timing for the intake and exhaust separately meaning more flexibility for tuners.

Yes.. I said "tuned" my camshaft. You're probably thinking : I thought you said the SOHC cams were fixed?.

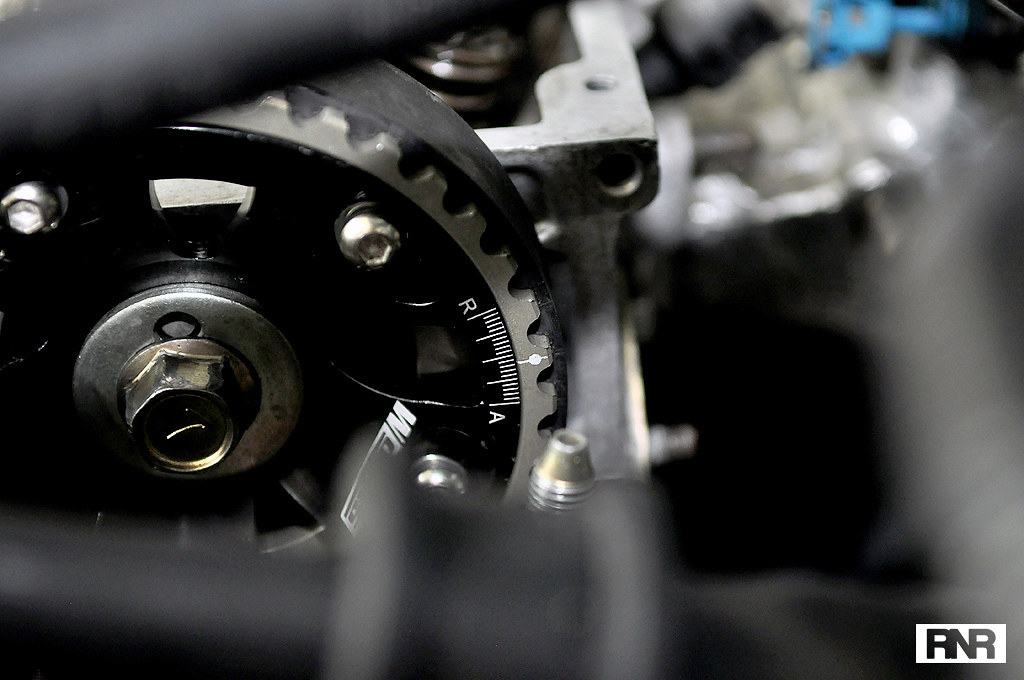

They are. But you can still fiddle with the angle of the lobes with an adjustable cam pulley. Depending on your car, retarding 2 degrees or advancing 2 degrees will shift the powerband for a SOHC car quite significantly.

There's nothing much else to explain. If you're using a stock cam and your car is a SOHC, I'm not quite sure what adjusting the angle of the cam will do. But stock power is pretty... stock. Why would you want to shift the powerband?

Picture courtesy of Zerotohundred.com @ Andysky5

Picture courtesy of Zerotohundred.com @ Andysky5

Lastly - engine dynamics, specifically engine balancing, blue printing, lightening and port & polish.

What is engine balancing, blue printing and lightening?

Your engine is made up of rotating and/or moving parts. These rotating parts create a certain force which if imbalanced (even the slightest) will cause vibration which causes stress and higher wear and tear on engine components.

Balancing essentially means you reduce this vibrational force. The lesser the vibration the better the part moves/rotates and the more efficient it is. If you've ever played with the Mitsubishi Evo's balancing shaft, you'd know what a really well balanced part is. The Evo uses a balancing shaft to counter the engines vibrational forces and the shaft is so incredibly balanced that if you were to rock it on a table, left alone it'll rock left, right, left, right (and so on) for a good 5 minutes before it eventually stops rocking.

Blue printing is basically re-machining every single component in your engine to achieve even better levels of balance.

Lightening is indirectly related and you essentially just lighten internal engine components before you send them for balancing. One of the more popular lightening techniques is "knife edging" the crank shaft. The crank shaft has large and heavy counter weights, what folks do is they slice off a lot of the counter weight to dramatically lighten the crank shaft.

The only downside to doing all this is this : when you balance your crank shaft, you'll have to do it with the whole crank assembly, meaning crankshaft and crank pulley. In my case my balanced pulley broke after a years usage and I had to replace it with another stock pulley. Problem is - the pulley is no longer balanced with the shaft and that means vibrational forces is back and resulted in a damaged/worn pulley in less than a year. In fact I had to replace 3 pulleys before I relectantly spent a small sum to rebalance the whole assembly. The same applies for clutches and clutch housings, if that is dynamically balanced with the rest of your engine that means every time you change clutch, you need to re-balance it.

So think carefully before you choose to balance your engine.

Picture courtesy of Zerotohundred.com @ TAQU

Picture courtesy of Zerotohundred.com @ TAQU

Port and polish is pretty straight forward. You know air flow is fast and you want air to flow in as smoothly as possibly. So a good port and polished cylinder head will do exactly that - let air flow as smoothly and uninterrupted as possible. This isn't something you can DIY unless you understand fluid dynamics so if you want it done, find a reputable tuner to do it for you. A poorly done up head will completely ruin your engine so choose wisely. Remember - you don't only want more air to flow in, your goal is to allow air to flow in as smoothly and quickly as possible.

That's it for basic NA mods.

Next up - forced induction and engine management.

Part #4 - More engine mods!

- Izso